Products

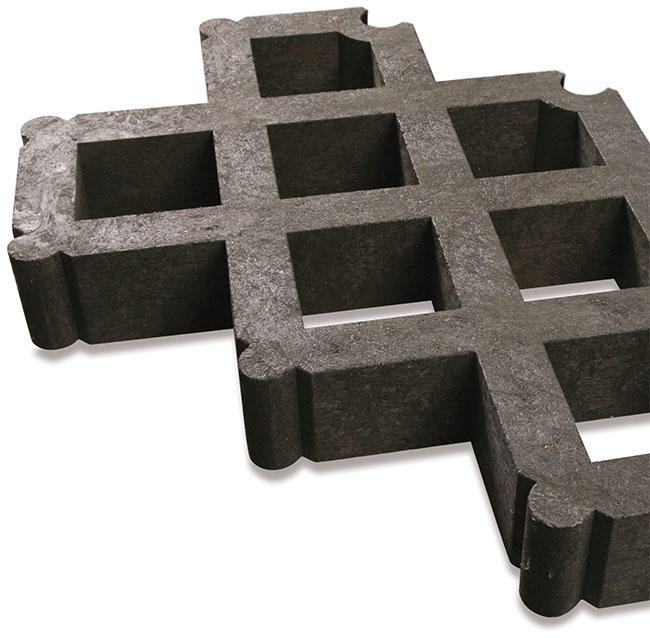

Truckpave™

Permeable paving grids for permanent grassed or gravel HGV access roads, HGV yards, fire access routes, coach parks and car parks where a structurally-sound, well drained base is to be installed.

Frequently Asked Questions

What markers are available for parking bays?

Snap-fit markers are available for both Bodpave 40 and 85. Different methods for delineating parking bays are available for Truckpave installations including the use of different coloured aggregate and conventional line painting.

What makes Terram Bodpave™/Truckpave™ better than alternatives?

Market leading TERRAM porous paving products have been subjected to rigorous laboratory tests to determine their suitability for use and have been installed on numerous projects throughout the UK for decades with a proven track record. TERRAM provides site specific design advice based upon decades of experience to ensure a successful installation. TERRAM offers impartial design advice and will only suggest the use of porous plastic paving for appropriate projects.

What Porous Paving Grids should I use?

For car parking bays and overspill car parks only, we suggest using Bodpave range. Specifically, Bodpave™ 85 is suitable for car parking bays and occasional HGV overrun. For car parks, HGVs, and coach parking bays, we suggest using Terram Truckpave™.

Please note that Bodpave™ 40 units are generally ideal for car parking bays and overspill car parks. However, for car/coach parking and occasional HGV overrun, we recommend Bodpave™ 85 units. As for Lorry, coach, and car parks, Truckpave™ is the recommended choice. For more detailed information, please consult the Terram technical department.

What vehicle weights will the units support?

All TERRAM Bodpave and Truckpave units can support light vehicles as the gravel or structural soil fill carries most of the load. TERRAM Bodpave 85 and Truckpave units can support occasional and regular HGV overrun respectively. It is more important to consider the dynamic loadings resulting from turning, braking, accelerating and slewing (“dry” steering).

What is compressive strength?

In the context of paving units, compressive strength is a measurement of the maximum load a unit can transmit downwards without breaking or crushing excessively. It is important to apply a factor of safety when comparing the maximum or ultimate compressive strength vs the anticipated loading or the units will deflect excessively.

Original &

The Best