Civil Engineering & Building

Warning & Detection

Frequently Asked Questions

What is a Geotextile?

A permeable highly durable synthetic fabric general used in Civil Engineering and Building projects such as road and car park construction to stabilise loose soil and prevent erosion. TERRAM geotextiles are highly permeable nonwoven needle punched and thermally treated synthetic fabrics made from polypropylene used to separate, filter, reinforce, protect, or drain engineering soils. Typical uses include preventing intermixing of granular sub-base and subgrade layers, drainage and bedding materials. TERRAM geotextiles help reduce wastage/loss of expensive imported granular materials, improve structural performance and extend the life of the pavement/road/rail track.

What is a Terram Geotextile used for?

TERRAM geotextiles are predominantly used for separation and filtration of fill materials preventing intermixing and extending the service life of unbound materials. TERRAM geotextiles can also be used to provide puncture resistance and reinforcement in certain applications.

What is the design life of a Terram Geotextile?

When designed, installed and maintained in accordance with the published literature most TERRAM geotextiles are sufficiently durable to achieve a design life of at least 100 years in most typical soil conditions. Please refer to DoP (Declaration of Performance) certificates for specific product grades which state the anticipated design life based on independent durability testing.

What grade of Terram Geotextile do I need?

TERRAM T1000GT standard geotextile is the most commonly specified separation & filtration geotextile in the UK and is fit for most but not all conditions. Ground conditions (type of soil, strength and permeability), type & size of aggregate fill, size of compaction equipment, traffic loadings (weight & frequency) will all affect the grade of TERRAM geotextile required. Please refer to TERRAM specification, design and installation guidance for more details.

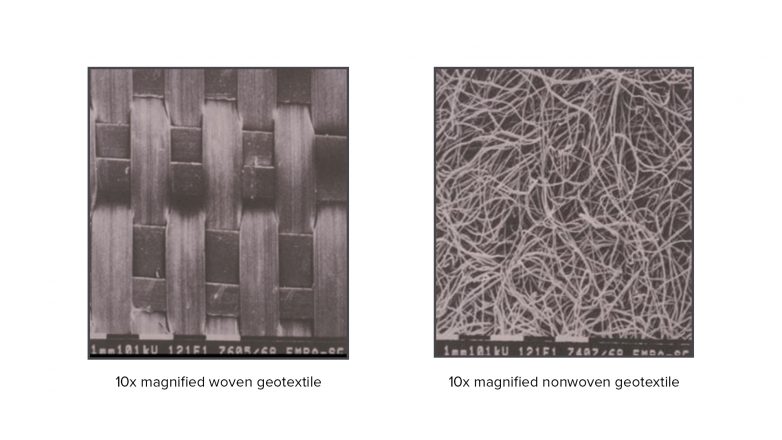

What is the difference between a woven and nonwoven (Terram) geotextile?

A woven geotextile is manufactured from continuous filaments or strips of synthetic material which are woven together to form a uniform sheet. A woven geotextile has a very uniform pore size which varies under load making them less suitable for filtering anything other than clean single sized soils/fills. Nonwoven geotextiles are a tangled web of fibres mechanically and/or thermally bonded together to form a non-uniform random web. Nonwoven TERRAM geotextiles have a wide range of pore sizes which make them ideally suited for filtering many different types of fill materials including well graded materials even under varying load conditions.

How do you joint Geotextiles?

Jointing TERRAM geotextiles can be achieved by overlapping, sewing, stapling or bonding. The simplest and most common jointing method is overlapping with overlap widths varying between 300mm and 1m depending upon the ground conditions and function of the geotextile. Please refer to TERRAM specification, design and installation guidance for more details.

What is pore size?

Pore size is a measurement of the gaps between the fibres within a permeable material such as a geotextile. TERRAM nonwoven geotextiles consist of a tangled web of randomly orientated polypropylene fibres, which result in a wide range of different size pores (gaps) ideal for filtering soil particles of different sizes, (gravels, sands and course silts) yet allowing the passage of water. Samples are tested in a laboratory to determine the range of pore sizes. To allow comparison between different geotextiles the apparent opening size (AOS) value is declared. The AOS is where 90% of the geotextile sample pores are of the same or smaller size (O90 value). The typical pore size allows designers to determine the suitability of a particular geotextile for filtering different grades of soil materials.

What is permeability?

The relative ability of a geotextile to allow the passage of fluids or gas, usually water. TERRAM nonwoven geotextiles have very high permeability compared to similar weight woven geotextiles. The permeability of a geotextile is determined by recording the water flow rate in a laboratory test.

What is puncture resistance?

The relative ability of a geotextile to resist objects or stones from bursting or pushing through the material. TERRAM nonwoven geotextiles have a high puncture resistance essential to resist construction damage during installation and placing of fill material with compacting equipment. Woven geotextiles generally have much lower puncture resistance and often (unseen) damage occurs during installation resulting in reduced performance or failure in the longer term. Static puncture resistance consists of pushing a 50mm diameter plunger through the geotextile and is measured in kN (higher is better). Dynamic puncture resistance consists of dropping a cone into the geotextile and measuring the size of the hole in mm (lower is better).

What is the coefficient of friction?

The typical coefficient of friction of a TERRAM geotextile is between 0.7 & 0.8 depending upon the amount of thermal treatment applied during production. Woven geotextiles generally tend to have a lower coefficient of friction between 0.5 and 0.8.

Original &

The Best